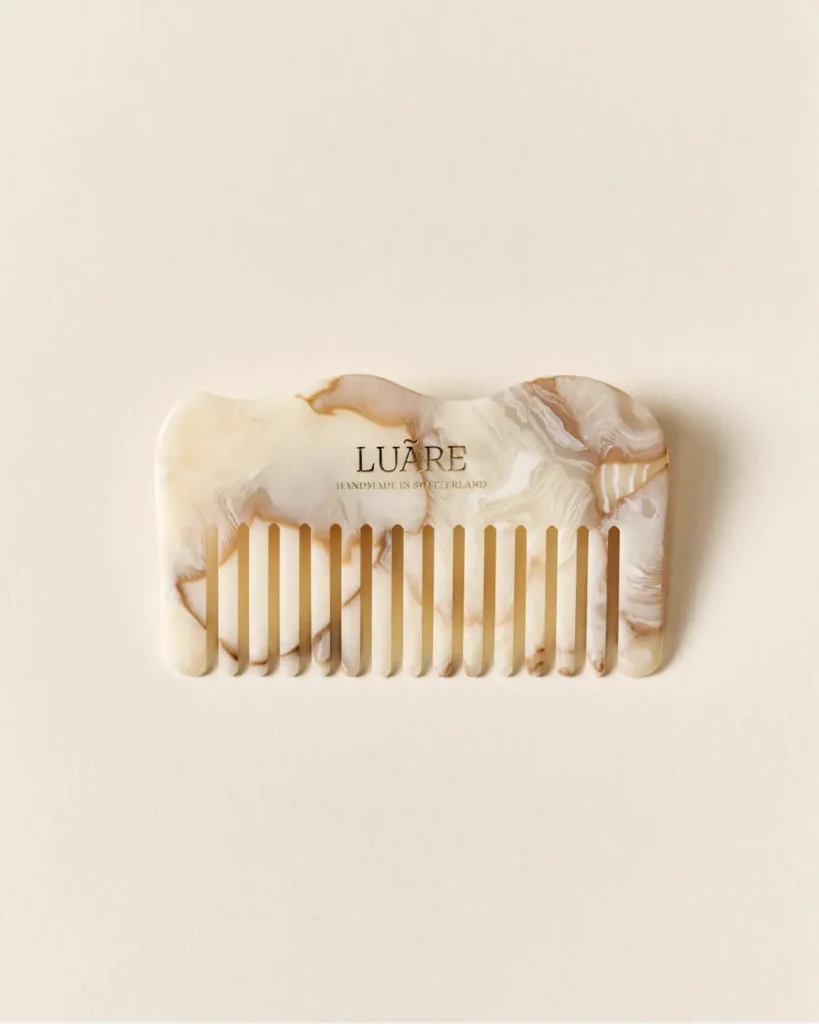

At Luare, we believe that something as simple as a comb can be a work of art—an everyday object elevated to extraordinary status. Our handmade fine combs are not just tools for your hair; they’re a testament to craftsmanship, innovation, and the pursuit of perfection. Each one takes 30 days and 22 steps. How this is even possible?

Creating a Luare comb is a meticulous process, combining artisanal skill and innovative technology. Here’s how we turn fine sheets of cellulose acetate into The Coastal Comb – one of the most luxurious combs in the world:

1. Raw Material Selection

It all begins with carefully selected cellulose acetate sheets. Each slab undergoes rigorous quality control, inspected under special lenses to ensure it meets our exacting standards.

2. Manual Shearing and Sizing

The acetate sheets are manually trimmed to size, preparing them for the next stage. This initial cut ensures each sheet is ready for individual die-cutting.

3. Manual Die-Cutting

Using custom-made steel dies, the sheets are cut into the rough shape of the comb. This is the first glimpse of the final design.

4. Tumble Sanding

The rough-cut pieces are placed in proprietary tumbling machines, where they are gently smoothed using special materials. This process removes burrs, splinters, and sharp edges.

5. Mechanical Profiling

Precision machinery contours the comb’s edges, ensuring every piece is smooth and stylistically perfect—even for the most intricate shapes.

6. Mechanical Chamfering

Next, the combs are further refined. Proprietary machines add precise details to the design, giving the comb its unique and distinctive character.

7. Manual Chamfering

Artisans take over, using small tools to hand-finish each comb’s contours. This step ensures a level of smoothness and polish that only human touch can achieve.

8. Raking (Cutting the Teeth)

The teeth of the comb are cut with millimeter precision using proprietary equipment. This step ensures flawless functionality and an unparalleled glide through hair.

9. Manual Grinding

Each tooth is manually smoothed, guaranteeing comfort and usability. This delicate process perfects the comb’s tines.

10. Interstitial Micro-Finishing

The area connecting the comb’s teeth to its back is carefully polished by hand. This ensures a smooth, harmonious finish for the most delicate combing experience.

11. Hot Blowing

Pre-heated compressed air cleans the combs, removing any impurities from previous steps and preparing them for further finishing.

12. Precision Mechanical Sanding

The combs’ surfaces are refined through a multi-step sanding process. Special belts and counter-belts remove even the tiniest imperfections, leaving the surfaces flawlessly smooth.

13. Manual Glazing

Proprietary tools add subtle bas-reliefs to the combs, enhancing their design. This step marks the end of the structural crafting phase.

14. Slow Rotary Washing

The combs are gently washed in custom-built machines to remove any residues from the manufacturing process.

15. Dynamic Drying

A controlled drying process ensures no moisture remains, leaving the combs perfectly prepared for finishing.

16. Mechanical Brushing

Soft grinding wheels brush each comb, removing any final micro-residues and further refining the surface.

17. Rotary Mechanical Tumbling

This multi-day process includes four stages—roughing, sanding, polishing, and brightening. The combs are tumbled in proprietary containers filled with special pastes and abrasives, resulting in a stunningly smooth and glossy finish.

18. Final Blowing

Cool compressed air removes any remaining particles, ensuring the combs are impeccably clean.

19. Special Processes

Some combs receive additional treatments, such as metal accents or integrated cases, adding unique touches to the final design.

20. Quality Control

Every comb undergoes a rigorous quality check, adhering to the highest “Swissmade” standards. Each piece is inspected for perfection in both form and function.

21. Final Polishing

The combs are hand-polished to achieve a luminous, mirror-like finish.

22. Manual Hot Stamping

Each comb is stamped with “Handmade in Switzerland,” marking its authenticity and exclusivity.

23. Manual Packaging

Finally, the combs are carefully packaged by hand, ready to make their way to you.

This painstaking process, rooted in centuries-old craftsmanship and enhanced by modern innovation, is what makes Luare Coastal Combs truly one of a kind. Each comb tells a story of artistry, precision, and dedication—ready to become a part of yours.

Discover Our Collection

-

Variant Product

The Coastal Comb

65 € Select options This product has multiple variants. The options may be chosen on the product pageRated 5.00 out of 5